|

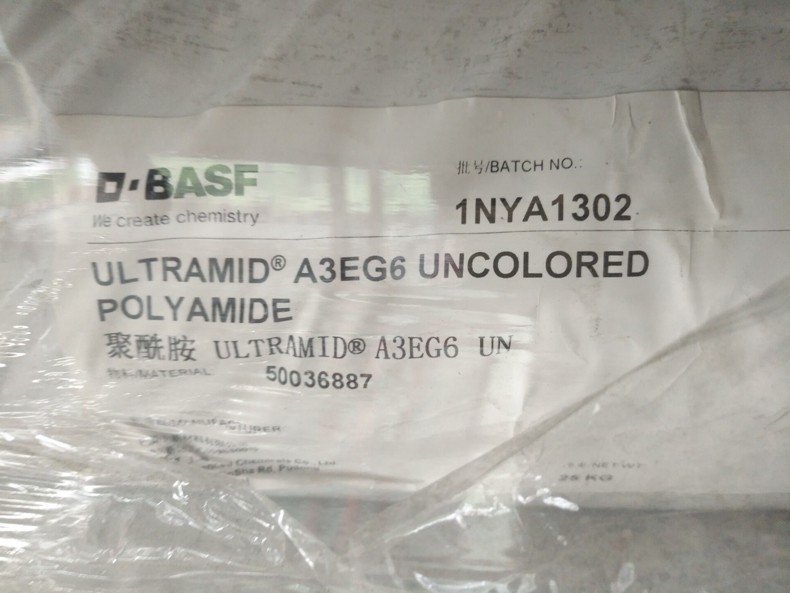

| 品牌 | *巴斯夫 |

| 货号 | 1234 |

| 用途 | 塑胶产品 |

| 牌号 | 8253 HS |

| 型号 | 8253 HS |

| 品名 | PA66 |

| 外形尺寸 | 25*25 |

| 生产企业 | *巴斯夫 |

| 是否进口 | 是 |

PA6 8253 HS 巴斯夫价格

技术参数

| 性能项目 | 试验条件[状态] | 测试方法 | 测试数据 | 数据单位 | |

| 物理性能 | 比重 | ASTMD792 | 1.09 | g/cm3 | |

| 密度 | ISO1183 | 1.09 | g/cm3 | ||

| 收缩率-流动(3.18mm) | 1.2 | % | |||

| 吸水率(24hr) | ASTMD570 | 1.5 | % | ||

| 吸水率(23°C,24hr) | ISO62 | 1.5 | % | ||

| 吸水率(饱和) | ASTMD570 | 8.1 | % | ||

| 吸水率(饱和,23°C) | ISO62 | 8.1 | % | ||

| WaterAbsorption(Equilibrium,50%RH) | ASTMD570 | 2.3 | % | ||

| 吸水率(平衡,23°C,50%RH) | ISO62 | 2.3 | % | ||

| 机械性能 | 拉伸模量 | -40°C | ISO527-2 | 2840 | MPa |

| 23°C | ISO527-2 | 2300 | MPa | ||

| 80°C | ISO527-2 | 400 | MPa | ||

| 120°C | ISO527-2 | 295 | MPa | ||

| 150°C | ISO527-2 | 250 | MPa | ||

| 抗张强度 | 屈服,-40°C | ASTMD638 | 117 | MPa | |

| 屈服,23°C | ASTMD638 | 65.0 | MPa | ||

| 屈服,80°C | ASTMD638 | 25.0 | MPa | ||

| Yield,121°C | ASTMD638 | 20.0 | MPa | ||

| 拉伸应力 | 屈服,-40°C | ISO527-2 | 117 | MPa | |

| 屈服,23°C | ISO527-2 | 60.0 | MPa | ||

| 屈服,80°C | ISO527-2 | 25.0 | MPa | ||

| 屈服,120°C | ISO527-2 | 20.0 | MPa | ||

| 屈服,150°C | ISO527-2 | 15.0 | MPa | ||

| 抗张强度 | 断裂,-40°C | ASTMD638 | 100 | MPa | |

| 断裂,23°C | ASTMD638 | 60.0 | MPa | ||

| 伸长率 | 屈服,-40°C | ASTMD638 | 7.0 | % | |

| 屈服,23°C | ASTMD638 | 4.0 | % | ||

| 屈服,80°C | ASTMD638 | 29 | % | ||

| Yield,121°C | ASTMD638 | 34 | % | ||

| 拉伸应变(屈服,23°C) | ISO527-2 | 4.0 | % | ||

| 伸长率 | 断裂,-40°C | ASTMD638 | 9.0 | % | |

| 断裂,23°C | ASTMD638 | >100 | % | ||

| 标称拉伸断裂应变 | -40°C | ISO527-2 | 9.0 | % | |

| 23°C | ISO527-2 | 40 | % | ||

| 弯曲模量 | -40°C | ASTMD790 | 3050 | MPa | |

| 23°C | ASTMD790 | 2210 | MPa | ||

| 65°C | ASTMD790 | 415 | MPa | ||

| 90°C | ASTMD790 | 325 | MPa | ||

| 121°C | ASTMD790 | 260 | MPa | ||

| 弯曲模量(23°C) | ISO178 | 1900 | MPa | ||

| 弯曲强度 | -40°C | ASTMD790 | 148 | MPa | |

| 23°C | ASTMD790 | 87.0 | MPa | ||

| 65°C | ASTMD790 | 25.0 | MPa | ||

| 90°C | ASTMD790 | 20.0 | MPa | ||

| 121°C | ASTMD790 | 14.0 | MPa | ||

| 弯曲应力(23°C) | ISO178 | 65.0 | MPa | ||

| 冲击性能 | 简支梁缺口冲击强度 | -30°C | ISO179 | 5.0 | kJ/m2 |

| 23°C | ISO179 | 18 | kJ/m2 | ||

| 简支梁无缺口冲击强度(23°C) | ISO179 | NoBreak | |||

| 悬壁梁缺口冲击强度 | -40°C | ASTMD256 | 80 | J/m | |

| 23°C | ASTMD256 | 150 | J/m | ||

| 落下冲击阻力(23°C) | InternalMethod | 271 | J | ||

| 硬度 | 洛氏硬度(R级) | ASTMD785 | 82 | ||

| 热性能 | 载荷下热变形温度(0.45MPa,未退火) | ASTMD648 | 168 | °C | |

| 热变形温度(0.45MPa,未退火) | ISO75-2/B | 160 | °C | ||

| 载荷下热变形温度(1.8MPa,未退火) | ASTMD648 | 60.0 | °C | ||

| 热变形温度(1.8MPa,未退火) | ISO75-2/A | 55.0 | °C | ||

| 熔融峰值温度 | ASTMD3418 | 220 | °C | ||

| 溶融温度(DSC) | ISO3146 | 220 | °C | ||

| 线形热膨胀系数-流动 | ASTME831 | 9.9E-5 | cm/cm/°C | ||

| 8.8E-5 | cm/cm/°C | ||||

| 线形热膨胀系数-横向 | 9.3E-5 | cm/cm/°C | |||

| RTIElec | 0.71mm | UL746 | 105 | °C | |

| 0.75mm | UL746 | 105 | °C | ||

| 1.5mm | UL746 | 105 | °C | ||

| 3.0mm | UL746 | 105 | °C | ||

| 6.0mm | UL746 | 105 | °C | ||

| RTIImp | 0.71mm | UL746 | 95.0 | °C | |

| 0.75mm | UL746 | 95.0 | °C | ||

| 1.5mm | UL746 | 105 | °C | ||

| 3.0mm | UL746 | 105 | °C | ||

| 6.0mm | UL746 | 105 | °C | ||

| RTIStr | 0.71mm | UL746 | 95.0 | °C | |

| 0.75mm | UL746 | 95.0 | °C | ||

| 1.5mm | UL746 | 105 | °C | ||

| 3.0mm | UL746 | 105 | °C | ||

| 6.0mm | UL746 | 105 | °C | ||

| 电气性能 | VolumeResistivity(1.50mm) | ASTMD257 | >1.0E+13 | ohms·cm | |

| 体积电阻率 | IEC60093 | >1.0E+13 | ohms·cm | ||

| 漏电起痕指数 | IEC60112 | 600 | V | ||

| 可燃性 | UL阻燃等级 | 0.75mm | UL94 | HB | |

| 1.5mm | UL94 | HB | |||

| 3.0mm | UL94 | HB | |||

| 6.0mm | UL94 | HB | |||

PA6 8253 HS 巴斯夫价格